INDUSTRIAL VISIT

Industrial visit to Toy Manufacturing Unit Channapatna Crafts Park

DATE: 17th January 2025

TIME: 9:00 AM – 4:00 PM

TITLE OF THE EVENT: Industrial Visit to Toy Manufacturing Unit

TARGET AUDIENCE: I and III semester MCom students

INDUSTRIAL VISIT BY: Industrial Visit Cell

FACULTY COORDINATOR: Ms. Chaithra H N

STUDENT COORDINATOR: Meghana B V

ABOUT THE EVENT:

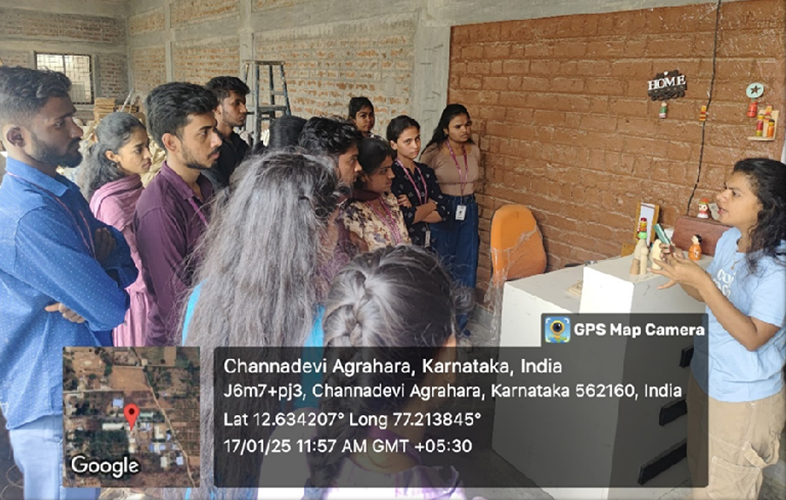

Industrial visit cell organized a visit to Toy Manufacturing Unit for I and III semester MCom students on 17th January 2025.

OBJECTIVES OF THE INDUSTRY VISIT:

- Industrial visits help students gain hands-on experience and bridge the gap between theoretical training and practical learning in a real-life environment.

- To gain insight into the production stages of toys, from design to packaging.

- To understand the impact of modern machinery, robotics, and 3D printing in toy design and production.

- To gain knowledge about the different materials used in toy production (e.g., plastics, metals, wood, and fabric).

- To understand the working environment and labour conditions in the manufacturing sector.

- To understand how toys are conceptualized, designed, and tested before production.

With an intention to provide exposure and to enhance the knowledge on various aspects of Industrial environment, I and III semester Mcom students were taken to Toy Manufacturing Unit in Channapatna on 17th January 2025. The batch consisted of 26 students and 1 faculty member.

DETAILS OF THE INDUSTRY VISIT:

During the industrial visit to the toy manufacturing unit, we learned about the unique and environmentally friendly production processes employed in the creation of organic, non-chemical-based wooden toys. The company uses natural materials such as turmeric for yellow colouring and coffee powder for brown, which are applied for customized orders, ensuring the toys are safe and free of harmful chemicals. A live demonstration showcased the transformation of a simple wooden piece into a beautifully finished doll. After the colouring process, the toy undergoes a smooth, glass-like finish using sandpaper to achieve a refined look.

The visit also included a demonstration of advanced machinery, such as the Laser Machine, capable of engraving designs up to 8mm in thickness. This machine allows for high levels of customization, enabling the creation of logos, family photos, keychains, and more intricate designs.

Additionally, we were introduced to the CMT Machine, which can cut materials up to 40mm in thickness. This machine is used for shaping various items, such as rainbow shapes, butterflies, name boards, and door designs. For the machine to process designs, the image or design is first saved onto a USB drive, which is then connected to the machine for precise cutting and engraving.

SUMMARY OF THE VISIT:

We arrived at the Toy Manufacturing Unit in Channapatna at 11:30 AM, where we were divided into two batches. The first batch, comprising III semester M. Com students, entered the facility, followed by the second batch of I semester M. Com students. Upon arrival, we were given an informative introduction to the toy manufacturing process, including the types of wood and natural colours used in the production of toys. The staff at the Toy Manufacturing Unit were exceptionally patient and cooperative, taking the time to explain the entire process of toy-making twice, once for each batch. A live demonstration was provided, illustrating how a simple wooden piece is transformed into a finished doll with a smooth, glass-like finish. Every step of the toy-making process was clearly explained, from the initial shaping to the final polishing.

Next, we were introduced to various machines, showcasing how advanced technology plays a significant role in the production of toys. We were able to observe first-hand how these machines function, producing toys of varying sizes. A key aspect emphasized during the visit was the commitment to manufacturing chemical-free, high-quality, and safe toys for babies and young children. Following the toy manufacturing demonstration, we visited a facility approximately 2.5 kilometres away, called Bharath Arts and Crafts, where the products are sold. The store featured a wide range of items, including keychains, dolls, magnetic vegetable sets, puzzle sets, couple toy sets, flower vases, and more. The quality of each product was excellent, and the prices were very reasonable.

After completing our visit and making purchases, we boarded the bus at 2:00 PM and returned to the college by 4:00 PM. Overall, the visit provided valuable insights into the craftsmanship and technological innovations involved in toy manufacturing, highlighting the company’s dedication to sustainable practices and customization. We gained a deeper understanding of the toy production process, the various machines used, and had an opportunity to conduct research on this fascinating industry.

OUTCOME:

- Industrial visit plays a very important role by encouraging innovative thinking and problem-solving in students by exposing them to real challenges faced by industries.

- Industrial visit enhances students’ knowledge in areas they may not have been exposed to in the academic studies.

- Industrial visit gives practical knowledge and hence we can say that all objectives have been achieved.